The best Solution to Labview

28.12.2022 If you’re a macOS user downloading packages for LabVIEW 2020 SP1 or later, take steps to configure VIPM and LabVIEW permissions to permit installation of LabVIEW packages in the proper location. This process is repeated until the user aborts this system. By keeping track of the variations between rotation of every motor, and using that distinction to adjust the motor power, this program ensures that the wheels rotate the identical amount. Kp is a proportional gain, it scales the distinction between the motor’s present place and the desired position-this difference is thought as the error. By taking the difference in rotation between the 2 motors and multiplying by a achieve, this system accounts for variations in motor distance. 2. Run the motor for 15 seconds. After resetting the timer, the program reads how long the loop has been working, subtracts the last timer value, and displays the end result to the display, essentially measuring the run time of one iteration. Examples of indicators are numeric indicators, gauge, LEDs, graphs, and other output displays. Controls, indicators, and constants function because the inputs and outputs of the block diagram algorithm.

If you’re a macOS user downloading packages for LabVIEW 2020 SP1 or later, take steps to configure VIPM and LabVIEW permissions to permit installation of LabVIEW packages in the proper location. This process is repeated until the user aborts this system. By keeping track of the variations between rotation of every motor, and using that distinction to adjust the motor power, this program ensures that the wheels rotate the identical amount. Kp is a proportional gain, it scales the distinction between the motor’s present place and the desired position-this difference is thought as the error. By taking the difference in rotation between the 2 motors and multiplying by a achieve, this system accounts for variations in motor distance. 2. Run the motor for 15 seconds. After resetting the timer, the program reads how long the loop has been working, subtracts the last timer value, and displays the end result to the display, essentially measuring the run time of one iteration. Examples of indicators are numeric indicators, gauge, LEDs, graphs, and other output displays. Controls, indicators, and constants function because the inputs and outputs of the block diagram algorithm.

On the entrance panel, the user inputs the specified place (in levels) of the motor. This program allows the person to enter a desired distance for an NXT automobile to maneuver forward. The consumer can even regulate the management beneficial properties, Kp and Ki which affects the enter power of the motor. On this explicit instance, the motor runs faster relying on which iteration the loop is on. For instance, by inserting a hundred into the numeric constant, the for loop executes a hundred instances before stopping. This instance shows the essential use of a shift register in a while loop. 1. This example makes use of a while loop and a shift register. The College of Engineering makes use of LabVIEW for many of its devices in its laboratories. The «brains» of K2’s ethernet-primarily based management system is a United Electronic Industries PowerDNA Cube that uses National Instruments’ LabVIEW, offering the ruggedness and extensibility that the NURTEC team at UConn needs for his or her underwater vehicle.

The system should be able to be managed manually or mechanically. System integrators, middlemen, and end users are just some of the various contributors that make up the market ecosystem that’s described. There are just a few completely different methods for developing a LabVIEW application that can communicate to a Galil motor controller. Unfortunately there will not be an open-source equivalent to this software, however there is some infra-construction which may very well be used to develop it. This error code indicates that there was a failed connection (right here as a result of choosing «OFFLINE»). Ki is an integral achieve, it scales the full accumulated error throughout the program. If essential, you may add a conditional terminal to configure a for loop to cease when a Boolean situation is met or an error happens. This instance exhibits how to make some time loop dependent on a condition in order to keep working, as a substitute of relying on a condition to be able to stop. 3. Stop the motor. These examples (ZIP) reveal motor management in LabVIEW. More lately, the availability of related modules akin to LabVIEW Real-Time, LabVIEW FPGA, LabVIEW Control Design and Simulation, and LabVIEW Statechart has positioned LabVIEW as a viable development software for real-time management and Mendota Heights Carpet Stretching embedded purposes.

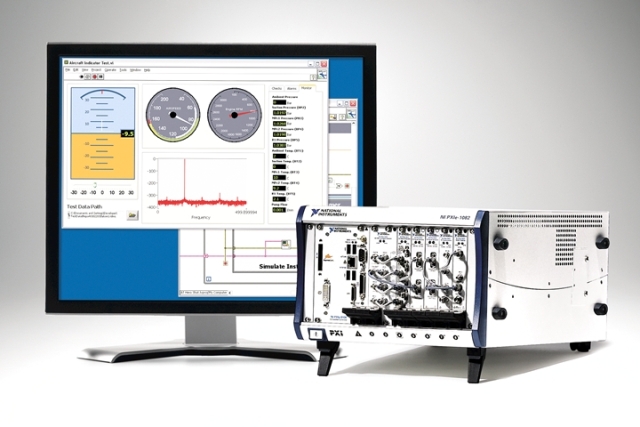

The positioning covers articles, tutorials, distributors, terminology, supply code (VHDL, Verilog, MATLAB,Labview), take a look at and measurement, calculators, information, books, downloads and more. Using LabVIEW, you’ll be able to create take a look at and measurement, information acquisitions, instrument management, datalogging, measurement evaluation, and report generation purposes. When the Add and Subtract functions full their calculations, they produce new knowledge values. Functions palette: We are able to find all of the commands that we need to create our program. 1. Select the commands you need. This device is used to pick varied commands. This software is used to wire the commands together. This tool is used to insert texts, and to alter the textual content or values. Front panel: That is the place we are able to insert charts, buttons and switches that we are able to use to regulate our robotic from the Pc. The software and driver described listed below are freeware to regulate Chemyx syringe pumps. Another necessary topic of this investigation is the extent of competition within the worldwide General-Purpose CAD Software market.